DrillFast

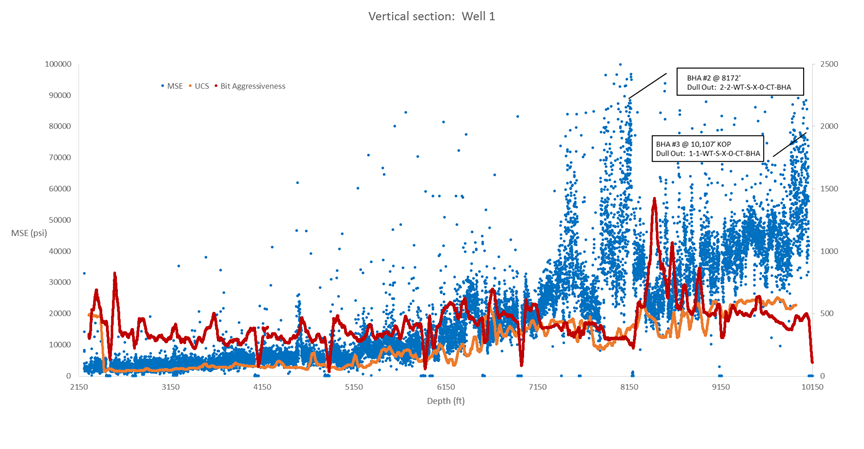

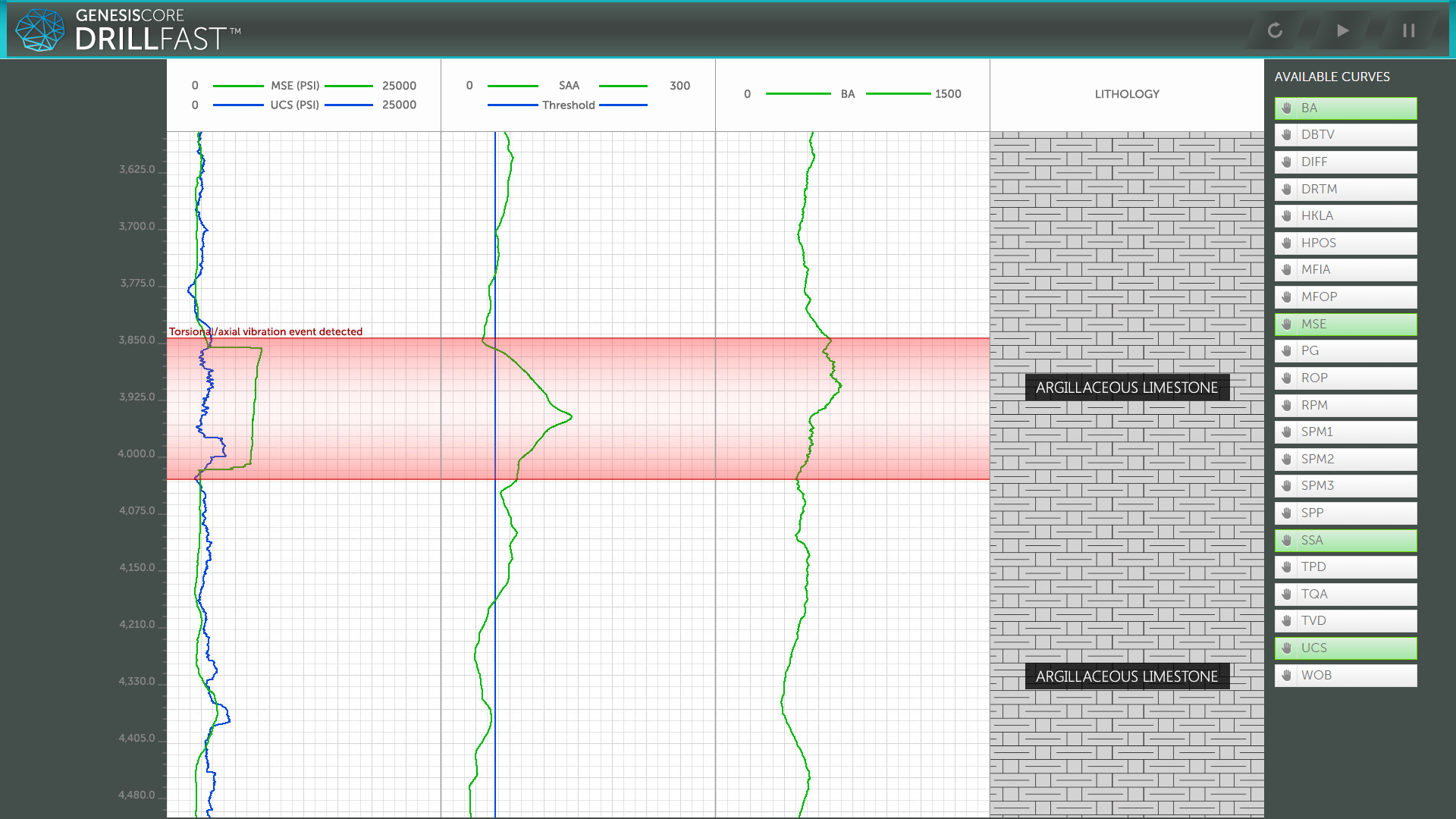

Under nominal conditions, MSE values should track with UCS. MSE values diverging with UCS indicate drilling inefficiency and potential problems.

Under nominal conditions, MSE values should track with UCS. MSE values diverging with UCS indicate drilling inefficiency and potential problems.

DrillFast is a state of the art drilling optimization tool that is designed to reduce your well delivery timeline by optimizing ROP, avoiding NPT from e.g. vibration-induced failures of drill string components, and reducing rig drilling performance deviations across your entire fleet. By specifically targeting drilling performance limiters in historical/post-well and real-time evaluations, DrillFast can reduce your well delivery time by as much as 30–50%.

DrillFast HISTORIAN

History is a great teacher. DrillFast provides the means to find and leverage the knowledge that is locked inside your historical drilling data. This tool will analyze historical drilling data, finding drilling technical boundary limiters while simultaneously identifying the root-causes of non-productive time events (premature bit damage, motor and drill string failures, non-responsive MWD/LWD equipment etc.) that are negatively affecting well delivery. From this analysis, DrillFast will provide recommendations along with coordinated performance indicators, allowing operators to easily identify drilling problem areas such as non-optimal hydraulics, harmful drilling vibrations, locate troublesome formations, as well as the optimum parameters to drill these. DrillFast Historian has been successfully applied in multiple geologically distinct drilling plays by using the fundamentals of drilling optimization with the following set of features:

- Complete field drilling optimization with the capability to quickly analyze hundreds of wells

- ROP analysis performed by hole section, activity, formation, bit size, bit type, etc. using time and depth based data

- NPT identification and analysis, with the ability to formulate improvement recommendations and scenarios

- Drilling KPI benchmarking, allowing for detailed post-well performance assessment and comparisons between wells, rigs and crews

- Creation of drilling learnings that can be shared among all affected stakeholders

DrillFast REAL-TIME

Optimized savings can be realized from real-time drilling performance optimization, and preventing problems caused by drilling dysfunctions, and by doing this consistently across the entire drilling fleet drilling in a certain geological play. We achieve this by analyzing rig sensor data in real time to derive key performance indicators with the intent of eliminating ROP limiters and preventing NPT events before they occur. This capability provides the following features:

- Automatic formation-based drilling parameter recommendations

- Monitoring real-time drilling parameters, looking for ROP limiters such as harmful drill string vibrations and ineffective hydraulics, and suggesting mitigation procedures

- Identifying the signs of impending NPT events such as twist-offs and mud motor failures, and recommending mitigation steps to prevent catastrophic failures from occurring

Features

- Use library of Mechanical Specific Energy (MSE) or customer derived equations to identify and characterize deviation trends from Unconfined Compressive Strengths (UCS)

- Correlate with other performance indicators such as Bit Aggressiveness (BA) and Stick-Slip Alarm (SSA) to confirm Rate of Penetration (ROP) limiters and recommend operational responses

- NPT Pattern recognition based upon historical cases for use in future drilling ventures

- Algorithms identify best parameters from benchmark wells to create drilling road maps that improve ROP